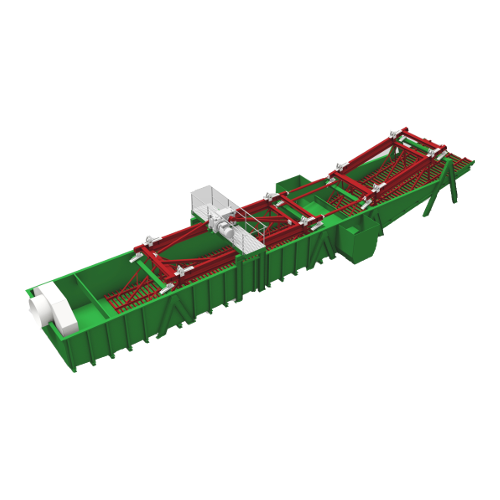

Rake clarifier

Description of the process:

During beet processing, all dirt particles that were delivered with the beets are removed while floating in and during water washing. Any impurities that are not removed in the existing drum and belt type rock catcher and gravel catcher remain in the water. For mechanical water treatment, our settling basins are, in addition to low operational costs, the most effective treatment plants for waste water. When the waste water has a high sand content or small organic particle, we recommend installing our screen grit classifier followed by a flume water filter into the water cycle. The screen grit classifier separates sand particles and therefore reduces the load on the settling basins. Post-liming of the flume water is reduced and costs can therefore be lowered.

Rake clarifier description:

The rake clarifier is built in a compact sheet steel construction. The waste water to be purified is passed through a pipeline into the water delivery container and into the separator tank. The large change in cross-section releases the water and the flow rate increases very sharply. The waste water flows slowly to the water overflows, which are positioned centrally in the rake clarifier, and move on for further processing. Sand particles sink to the bottom of the rake clarifier and are conveyed to the discharge side via two rakes, which are positioned directly above the base tray and connected to one another using a special articulated system. Motion is provided with an oscillating pushing-lifting motion. The settled sand is conveyed forward across the course, across the sturdily assembled rakes. During the lifting motion, the entire rake lifts and moves opposite to the direction of conveyance, tilts back and starts again with the conveyance of the settled particles. The discharge proportion goes from a horizontal to an increasing proportion. The inclined discharge area lies above the water level before the discharge edge. This way, the sand is further dewatered before being discharged.