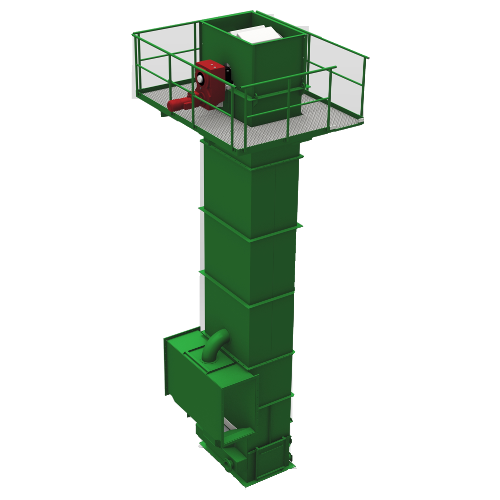

Belt type rock catcher

The Glaß & Wolff belt type rock catcher consists of a capture trough followed by a belt elevator. The belt type rock catcher is used for the separation of stones from the crop-water

mixture. In general, the belt type rock catcher is installed in deep troughs below the base. Some customers also install this machine above the sole in existing gutter systems. The belt type rock catcher requires an external water supply to separate the crop from the stones. This can on the one hand be provided from a supply tank through an adjustable valve, or via a frequency-controlled pump.

The amount of water supplied determines the degree of separation. The beet-water mixture is floated down the channel. The area of the capture trough, which has a stonefall aperture in its base, is flushed from the inside out with the externally supplied water. The water pressure determines the amount of flotation water that flows through the stonefall aperture. The crop is flushed to the surface with the flotation water. The stones sink into the stonefall aperture due to their specific gravity against the flow of water.

The stones slip down a stone chute located in the interior and into the bucket elevator. The bucket elevator is an inner bucket system, where the buckets are hermetically screwed to a special steel-reinforced rubber belt. The steel-reinforced rubber belts remain stable for years, in comparison to chain bucket elevators. The buckets transport the stones from the pit and deposit the stones in a stone removal chute located at the head of the machine for further applications.