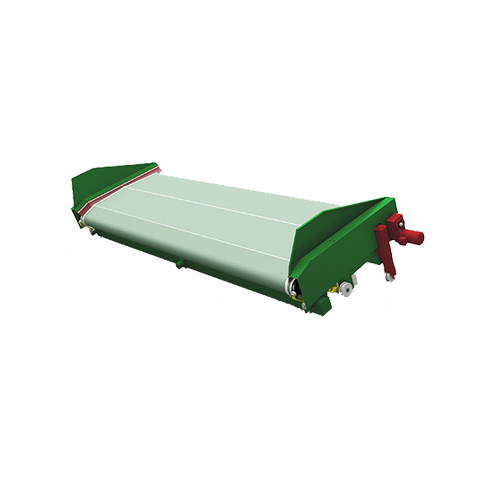

Separating belt

The Glaß & Wolff separating belt is used for separating beet fragments and leaves. The separating belt consists of a robust frame with a pivot mounted control platform over the centre. Drive and tail drums and two polygonal drums are mounted on the frame and on the control platform above stable spherical roller bearings. A webbing belt specially produced for this purpose completes the machine. In order to ensure stable running of the belt, the control platform can be moved via a mechanical controller, and the belt’s velocity will adjust accordingly. The adjustment equipment has been redesigned and can easily be operated by the client’s own personnel. A special lifting device controls the tilt adjustment of the separating belt.

The separating belt is constructed together with the flume water filter as one beet fragment processing unit in almost all refineries. The separated organic items, consisting of beet fragments and leaves, are removed from the flume water filter constructed above the separating belt. At the separating belt, one can distinguish between the consistencies of organic matter for rolling beet fragments and fibrous leaf particles. The separating belt is adjusted to the desired position via the tilt adjuster.

The desired degree of separation for the individual portions is achieved through the specific tilt provided. The separating belt runs uphill against the direction of motion for the flume water filter above the belt. The separating belt’s fabric is vibrated by passing over the two polygonal drums. The leaf fragments remain on the separating belt’s fabric due to their consistency and are lifted to the apex of the drive drum and discarded. In the lower tower there is a belt scraper that scrapes off the remaining adhering leaf fibres. The beet fragments begin to “bounce” on the separating belt, which is achieved by the polygonal drums. The beet fragments on the separating belt hop against the running direction and the inclination set up to the tail drum and fall into the receiving basin. The beet fragments are returned to the process and the leaf fragments are ejected for further use or processed into pellets. Below the hoppers are screw conveyors or belt conveyors, which are also part of our portfolio.