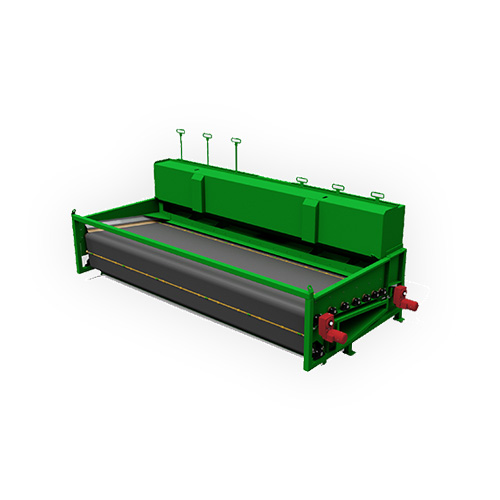

Flume water filter

Glaß & Wolff flume water filters are used successfully for fragment filtration in beet sugar refineries. After being filtered, the beet fragments and leaf fibres filtered from the wash water are released onto a separating belt. The fragments are separated from the leaf particles. The degree of separation is adjustable. In many refineries, beet fragments still containing sugar are recycled into production. In some cases, the investment is amortised within a single sugar beet campaign.

Our flume water filter is distinguished by its large water throughput. The filter widths and gap widths are variable. Another special feature is the filter mats, which are made of an extremely hard-wearing special plastic. The endless curtain of filter mats is assembled from individual filter mats with a special simplified connection technology. Individual filter mats are quick and easy to replace.

The water is filtered down to the gap width of the screen mats. Particles, particularly leaves and fragments, remain on the surface of the screen and are discarded in the direction of conveyance to the slightly rising crest of the drive drum for further processing. In the base of the tower there is a simple scraper, which also cleans the surface of the screen. The filtered water is passed through a closed internal water basin, which is also part of the filter frame, and then passed laterally to the water outlets.

Additionally, the load on in-site water treatment systems is greatly reduced by good pre- filtration.

The flume water filter is a screen belt filter that moves in a triangular motion. The flume water filter consists of a sturdy frame with a screw-mounted water distribution box. The contaminated water is deposited in the centre of the water distribution box. The flume water is uniformly distributed over the entire width of the filter. At the overflow, the flume water is passed over a guide plate on the surface of the screen.