Falling-film evaporator

In a multistage evaporation system, thin juice is concentrated into thick juice in the DC from the juice and broiling vapour. The guidance of the direct current complies with the sensitivity of sucrose solutions to high temperatures. In the evaporation system, the concentration is carried out continuously from step to step with falling pressure.

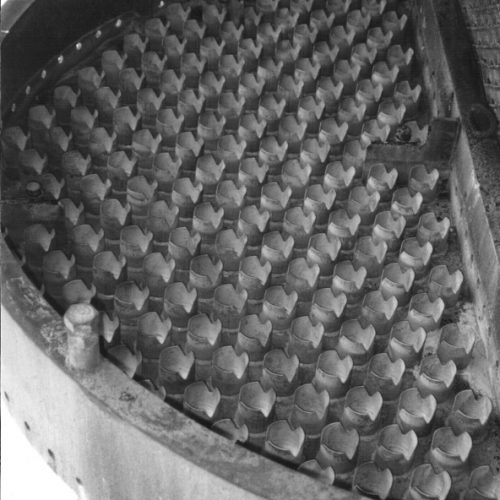

Evaporators are separated into falling film evaporators and rising film evaporators. Evaporators also exist where both variants can be combined. In the case of the falling film evaporator, the juice to be concentrated trickles from top to bottom through the heating pipes, with their vapours moving in the DC. In order to improve the partial revolutions, the tube wall must be used entirely along the tube length. In doing so, it is important that the juice emerges uniformly from the heating chamber pipes. Due to this, the heating chambers of the falling film apparatus have fewer, but also longer, pipes. Through internal calculations, we can create customised offers for each factory.

The Glaß & Wolff falling film evaporator differentiates itself from others through the low juice filling required and a low juice retention time. Another advantage of the Glaß & Wolff falling film evaporator is that this construction can be used even at low temperatures and for higher concentration.